The Role of an Optical Fibre Diameter Analyser in Product Inspection

The Role of an Optical Fibre Diameter Analyser in Product Inspection

Blog Article

Optimize Your Fiber Optic Performance: Understanding Optical Fiber Size Analyser Innovation

The performance of fibre optic systems is critically influenced by the precision of their size, a factor commonly neglected in the search of ideal signal stability. Comprehending the innovation behind optical fibre size analysers discloses the elaborate balance in between measurement accuracy and manufacturing top quality. These tools not only improve conformity with market requirements but likewise supply real-time insights that can preemptively attend to potential problems. However, the implications of their use extend beyond plain dimension; they can fundamentally alter the landscape of fiber optic performance. What variables should one think about to harness their full possibility?

Importance of Optical Fiber Diameter

The diameter of optical fiber plays a crucial function in establishing the performance and efficiency of communication systems. It affects a number of crucial parameters, consisting of the mode of light breeding, depletion, and bandwidth capability. Bigger diameters commonly permit numerous light settings, promoting higher data transmission rates. Alternatively, smaller sized sizes have a tendency to sustain fewer modes, which can improve signal clarity and minimize crosstalk.

Furthermore, comprehending the size's implications can lead to cost financial savings by decreasing the requirement for signal boosting and repeaters in comprehensive networks (optical fibre diameter analyser). In conclusion, the significance of optical fibre diameter can not be overemphasized, as it straight affects the total performance and integrity of modern-day communication systems

Exactly How Diameter Influences Signal Quality

Signal high quality in optical fiber systems pivots significantly on the diameter of the fibre. The diameter influences numerous vital specifications, including depletion, data transfer, and modal diffusion. A smaller diameter can bring about greater attenuation rates, resulting in signal loss as light trips through the fiber. This attenuation can compromise the honesty of the transmitted information, causing a decrease in signal quality, particularly over cross countries.

On the other hand, bigger sizes usually enable boosted light capture and decreased modal dispersion, enhancing signal clearness. In multimode fibers, a larger core size can sustain several light modes, however it may likewise introduce intermodal dispersion, which can degrade signal high quality. Consequently, selecting the optimal fiber diameter is vital for attaining the wanted efficiency in specific applications.

Additionally, the communication in between the fiber diameter and the wavelength of the light used plays a vital function in establishing the reliable transmission distance and total signal stability. Understanding exactly how fibre size affects signal top quality is vital for network developers and engineers striving to enhance optical fiber systems for trusted, high-speed information transmission.

Summary of Diameter Analyser Modern Technology

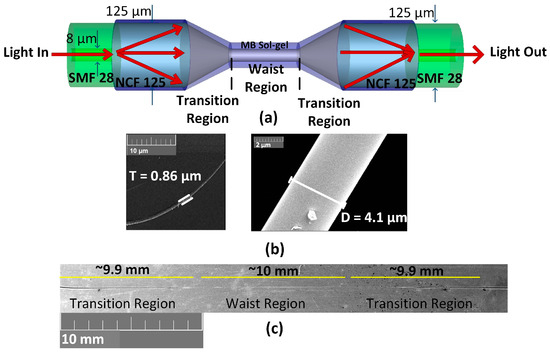

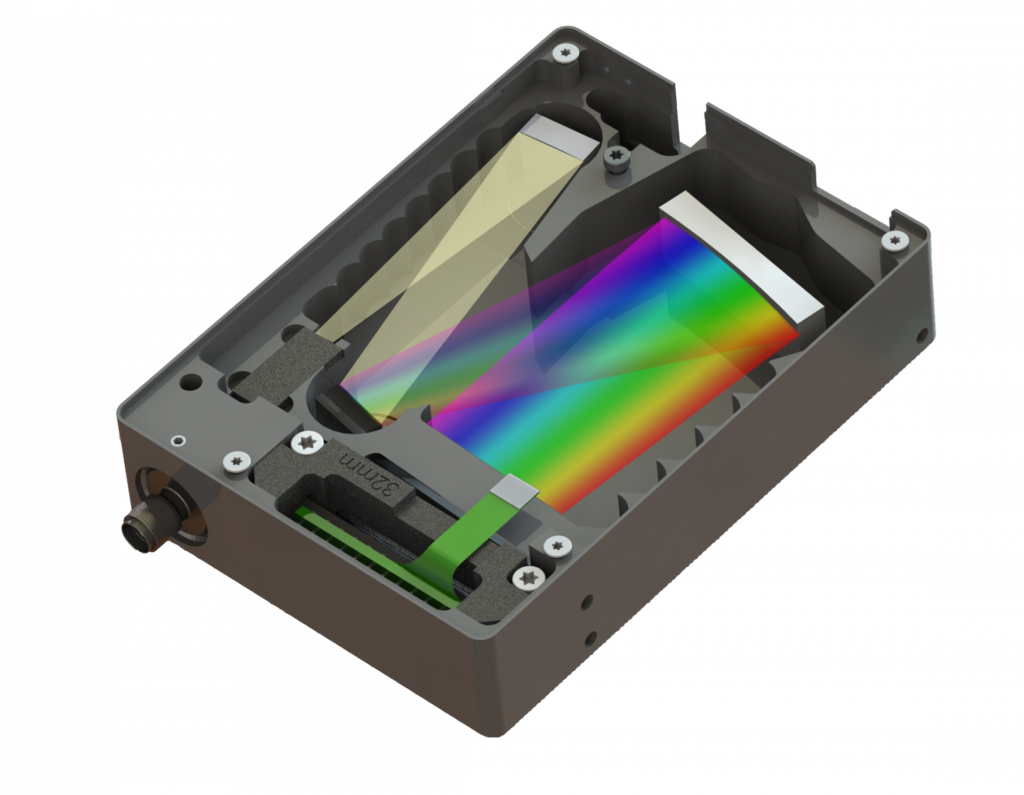

In several optical fibre production procedures, accurate dimension of fibre size is crucial for making certain constant performance and quality (optical fibre diameter analyser). Diameter analysers are innovative instruments created to assess the physical dimensions of optical fibres with high accuracy. They use sophisticated optical and laser innovations to measure the diameter, ovality, and concentricity of the fiber, therefore offering critical data for top quality control

These analysers can run in-line throughout the manufacturing procedure or as component of off-line screening procedures. In-line systems enable real-time tracking, allowing suppliers to change specifications immediately, thus keeping optimal production conditions. Off-line analysers, on the various other hand, offer next page thorough analyses of batches, ensuring that any deviations from specified tolerances are determined and attended to.

Diameter analysers significantly contribute to the decrease of flaws in optical fibres, boosting total item reliability. By consistently gauging crucial specifications, these modern technologies assist in compliance with industry criteria and specs. As the demand for high-performance optical fibers remains to climb, the function of diameter analysers ends up being progressively important in attaining the desired quality and performance requirements in fibre optic systems.

Key Functions of Fibre Diameter Analysers

Although numerous models of fiber try this size analysers exist, they commonly share several essential functions that boost their performance and reliability. One of the most considerable functions is high-resolution dimension capacities, which ensure specific size readings, critical for keeping top quality control in fibre manufacturing. Additionally, many analysers integrate innovative optical sensors designed to identify minute variations in fibre diameter, thus offering very useful data for procedure optimization.

One more crucial function is real-time tracking, allowing drivers to receive instant comments on fibre size throughout the manufacturing procedure (optical fibre diameter analyser). This capability assists in fast adjustments and lowers the likelihood of flaws. Many analysers additionally come geared up with user-friendly user interfaces, enabling drivers to conveniently navigate with settings and data results

In addition, durable information storage space and evaluation functionalities are crucial for tracking historic performance trends and making sure conformity with market standards. Some designs also use connectivity choices for combination right into existing production control systems, improving total operational effectiveness. Portable and small styles permit for versatile deployment within manufacturing settings, making sure that top quality guarantee processes are smooth and reliable. These functions collectively add to the effectiveness of fibre size analysers in optimizing fibre optic performance.

Best Practices for Fiber Optimization

First, normal calibration of optical click to read fibre diameter analysers is important. This guarantees exact dimensions and decreases possible inconsistencies that can affect efficiency. Next off, keeping a clean working setting is crucial; dust and pollutants can result in signify degradation.

Additionally, it is necessary to pick fibres that fulfill details application demands. This involves reviewing variables such as attenuation, data transfer, and ecological problems. Correct installment techniques ought to likewise be abided by, including avoiding sharp bends and too much tension, which can jeopardize fibre honesty.

Furthermore, employing sophisticated tracking systems can help with real-time performance evaluations, making it possible for punctual recognition of issues. Routine screening and maintenance must be conducted to make certain that fibers continue to be within optimal operational parameters.

Finally, training workers on the newest fibre optimization technologies and techniques will boost their capacity to carry out effective approaches. By following these ideal techniques, organizations can dramatically boost the performance and life expectancy of their optical fibre systems, guaranteeing reliable interaction and information transfer.

Final Thought

In final thought, the assimilation of optical fiber diameter analyser modern technology is crucial for making the most of fibre optic performance. By ensuring precise dimensions of fibre measurements, these analysers dramatically boost signal high quality and decrease losses during data transmission.

Signal high quality in optical fiber systems hinges dramatically on the size of the fiber.In lots of optical fibre production processes, exact measurement of fibre size is crucial for making sure regular efficiency and high quality. As the demand for high-performance optical fibres proceeds to climb, the function of size analysers becomes increasingly essential in accomplishing the preferred high quality and performance standards in fiber optic systems.

These attributes jointly contribute to the efficacy of fibre size analysers in maximizing fibre optic efficiency.

In conclusion, the integration of optical fibre size analyser innovation is critical for taking full advantage of fiber optic efficiency.

Report this page